Applications of polyethylene – how does PE foam protect products during transport?

Polyethylene is a material that has been changing the way companies protect their products during transport for years. Lightweight, flexible and extremely durable, in the form of foam it becomes a reliable ally in logistics. Thanks to it, even the most delicate goods reach their destination in perfect condition, and companies can count on lower losses and costs. Find out what applications of polyethylene make PE foam one of the most valued protective solutions in transport today.

Applications of polyethylene in transport – discover why PE foam is the silent guardian of your products!

In transport, one thing matters above all else – the safety of the cargo, regardless of whether it is delicate electronics, heavy industrial equipment or glass components. That is why polyethylene foam has become the basic protective material in logistics. Thanks to its elasticity, impact resistance and lightness, it effectively minimises the risk of damage without significantly increasing the weight of parcels. Importantly, the applications of polyethylene are not limited to one sector – this material is equally often used in road, sea and air transport.

Transport companies use PE foam because it provides cushioning even during prolonged vibrations and shocks that accompany transport. The closed-cell structure of the foam creates a barrier that absorbs impact energy and protects the product from moving around in the packaging. What is more, the foam does not absorb moisture, making it suitable for use in changing weather conditions where other materials fail. It is this feature that is causing more and more companies to abandon traditional film or cardboard in favour of polyethylene.

The economic aspect is also important – the use of polyethylene foams and inserts translates into real savings. Thanks to its reusability, this material is durable, resistant to damage and environmentally friendly, which is of great importance in times of rising logistics costs. In addition, PE foam can be easily cut, moulded and adapted to the shape of the product, which translates into a better fit for the protective packaging. As a result, there is less risk of damage, fewer complaints and more satisfied customers.

PE foam in action – how does the use of polyethylene minimise losses and complaints in logistics?

Transporting goods is not just about moving them from point A to point B – it involves the entire logistics of securing, storing and delivering them, in which polyethylene foam plays a key role. Logistics companies are well aware that any shock, fall or impact can result in financial loss. Therefore, the use of polyethylene foams as shock-absorbing elements can significantly reduce the number of complaints and returns. PE foam protects products not only from mechanical damage, but also from scratches, dust and moisture, which could reduce their value.

Foam fillings and filling foams for suitcases, which adapt to the shape of the transported item, are becoming increasingly popular. This solution is particularly valued in industries where precision and safety are of key importance, e.g. in the transport of electronics, measuring instruments, aerospace parts and medical equipment. PE foam can be cut to size to create perfectly fitting inserts that stabilise the product and prevent it from moving around in the packaging. This ensures that the goods arrive at their destination in the same condition as they were packed.

It is worth noting that polyethylene is a chemically neutral and odourless material, so it does not react with delicate surfaces such as glass, varnish or metal. This is another reason why logistics companies choose PE. What is more, the foam is easy to process and store, does not produce dust, does not absorb odours and can be reused – which is of great importance in the context of the circular economy. For many companies, it is a simple way to reduce losses and build an image of a company that cares about quality and the environment.

PE applications that make a difference – discover the advantages of polyethylene over bubble wrap and polystyrene!

Although there are many protective materials on the market, polyethylene foam clearly stands out from the competition. Compared to bubble wrap or polystyrene, it offers better flexibility and greater resistance to deformation. While bubble wrap loses its properties after a few uses, PE foam retains its full functionality even after many cycles of packing and unpacking. For transport companies, this means lower operating costs and less waste.

Styrofoam, on the other hand, is rigid and brittle, which can be problematic during transport. A strong impact is enough to break it, and its debris contaminates the product and the environment. PE foam works completely differently – it is flexible, resistant to compression and does not crumble, so it can be repeatedly moulded and adapted to different shapes. Foam fillings made of PE also make the packaging much more aesthetically pleasing – the product looks professional, which is important for premium deliveries.

What is more, PE foam is a low-density material, so it does not increase the weight of the shipment. This is a simple but very measurable advantage in transport – after all, every extra kilogramme means additional fuel costs. Unlike bubble wrap, which loses its elasticity over time, PE foam retains its cushioning properties, guaranteeing full protection even during long-distance transport. This is why more and more companies are choosing polyethylene as their primary protective material – durable, lightweight and economical.

Choose closed-cell foam – resistant to moisture, shocks and abrasion!

How to choose the right PE foam for transport? Practical tips to protect your goods from damage

Choosing the right PE foam is not just a matter of price – it is a decision that directly affects the safety and durability of the products being transported. Depending on the nature of the goods, it is worth paying attention to the type of material, as EPE foam and XPE foam differ in their properties and applications. The former – flexible and lightweight – is ideal for protecting lighter items, while XPE foam, with its cross-linked structure, provides greater rigidity and resistance to damage, making it suitable for more demanding loads.

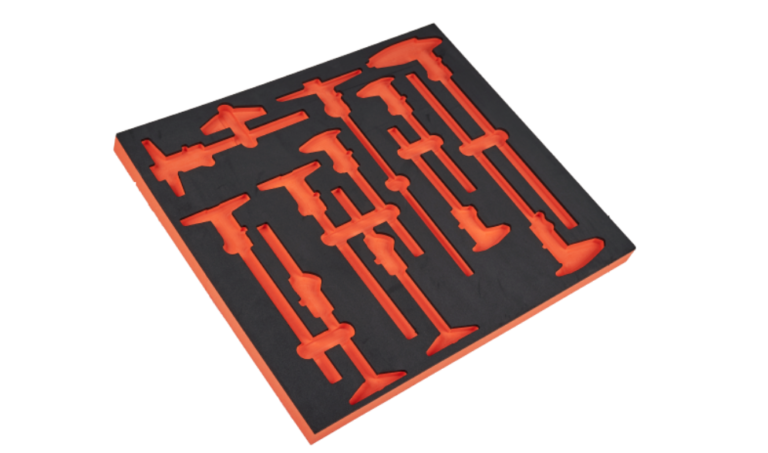

Transport companies are also increasingly investing in antistatic foam, which neutralises electrostatic charges and protects sensitive electronic components from damage. This solution is not only practical, but also raises the standard of security in the eyes of the customer. It is also worth remembering that PE foam can be cut and glued into any shape, which gives great freedom in designing individual packaging. Thanks to this, each shipment can have dedicated protection tailored to a specific product. For professionals transporting tools, a shadow board made of PE foam with precisely cut-out spaces for each piece of equipment is ideal. This solution not only keeps tools tidy and easily accessible, but also effectively protects them from shifting and accidental damage during transport.

In summary, polyethylene foam is a solution that combines functionality, durability and safety in one material. Its wide range of applications in transport makes it an indispensable element of logistics today – it protects products, reduces costs and allows companies to build an image of a partner who cares about every detail of delivery. If you want to ensure the safe transport of your products, choose proven PE foam solutions and see how much you can gain from proper load securing.

We share our expertise in the design and production of shadow boards, protective packaging, and inserts made from PE foam. For years, we’ve been supporting the aerospace, medical, and automotive industries by delivering solutions tailored to individual needs. We combine the precision of CNC machining with an eco-conscious approach and technical consulting. Our creations focus on quality, ergonomics, and reliability.