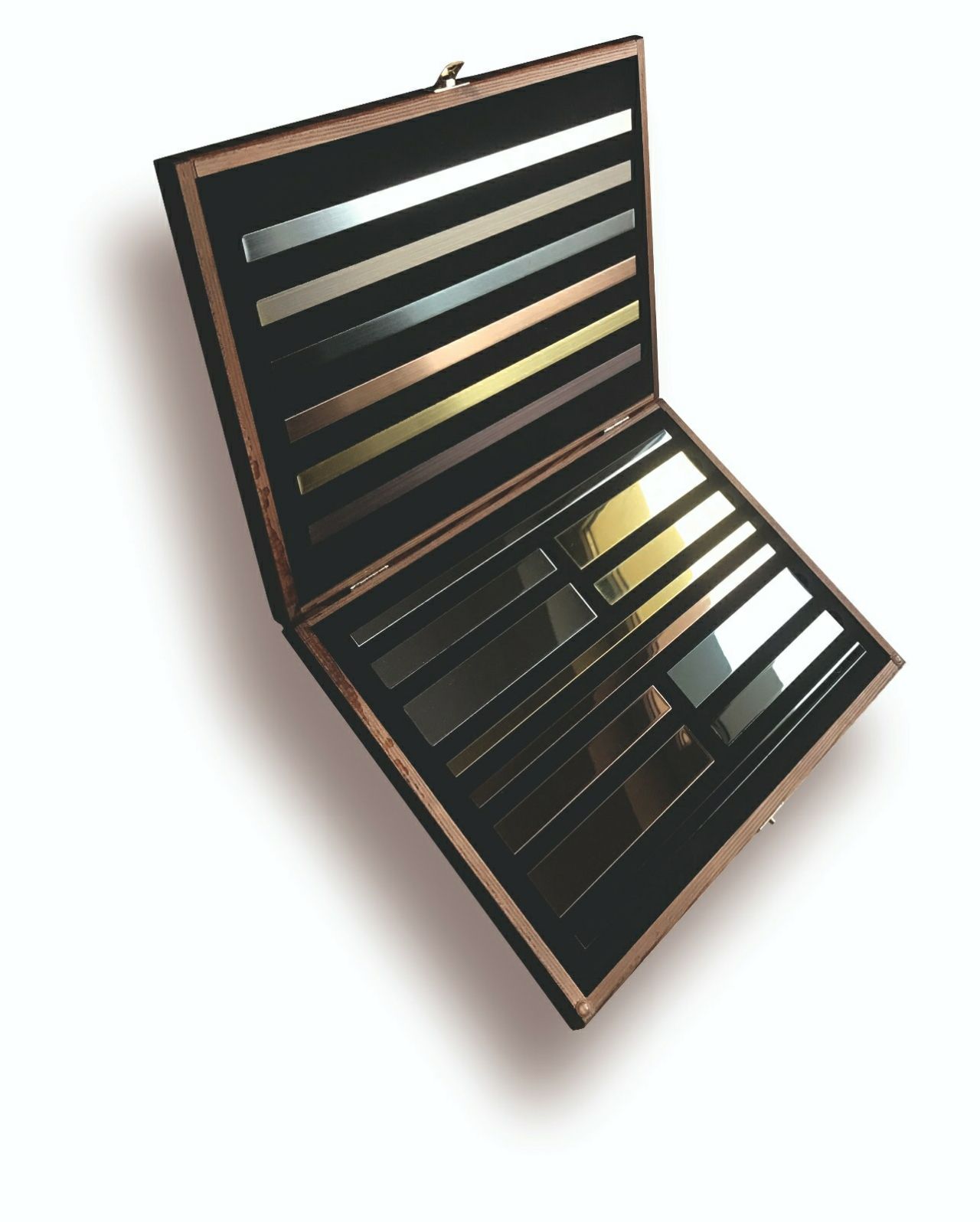

Our offer is addressed to both large manufacturing companies and retail customers who value individual approach, high quality of products and care about the environment, betting on reusable products. Especially for industries such as aerospace, medical and automotive, and any industry where it is important to account for all tools and parts before they leave the workplace.

Our experience offers the highest quality shadow boards and expertise in providing the best CNC design and machining solutions.

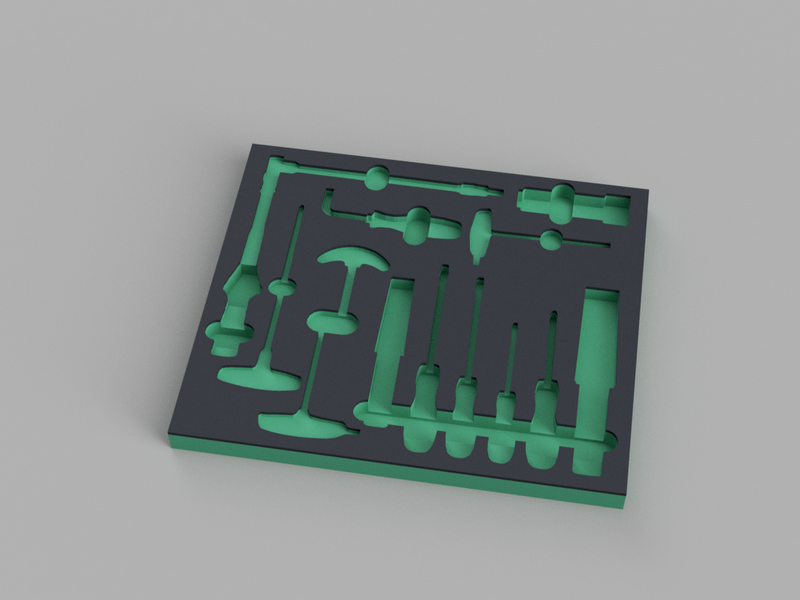

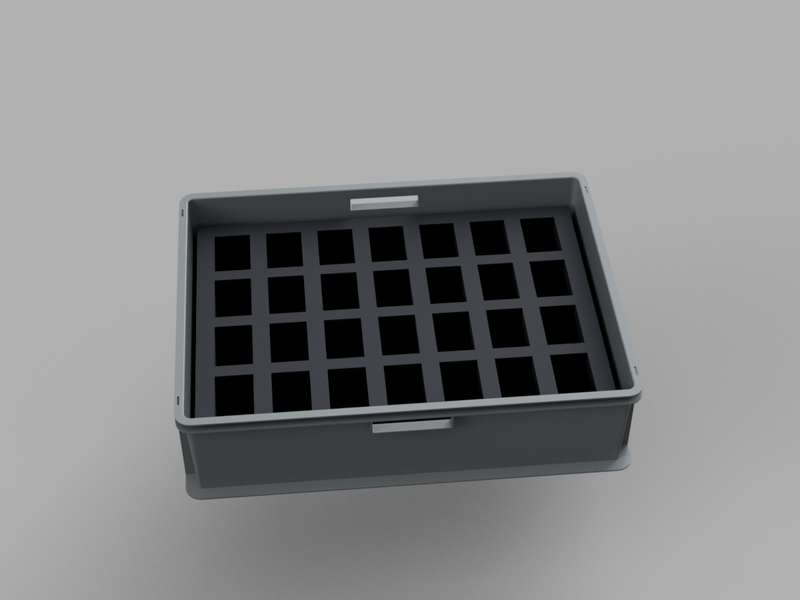

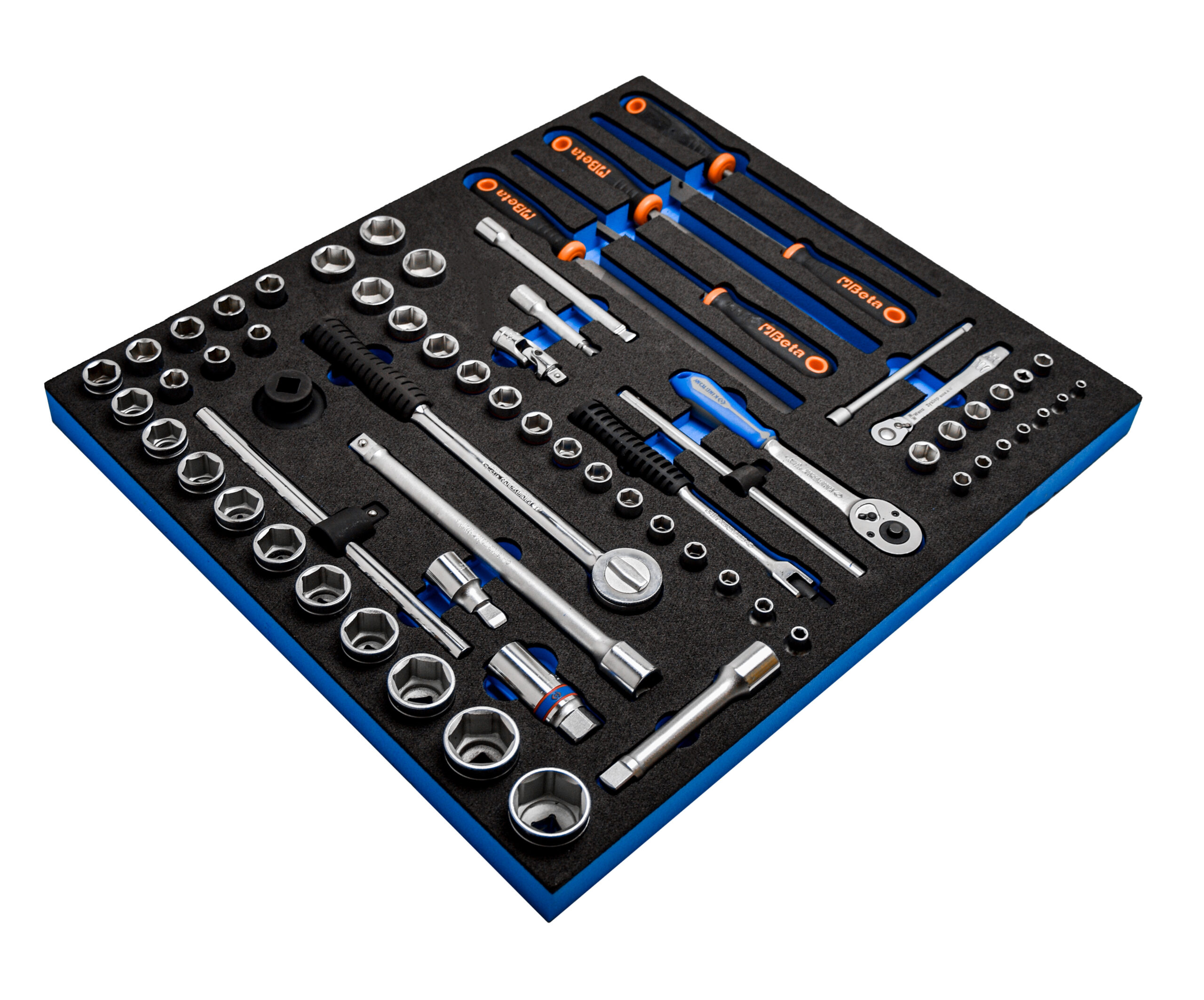

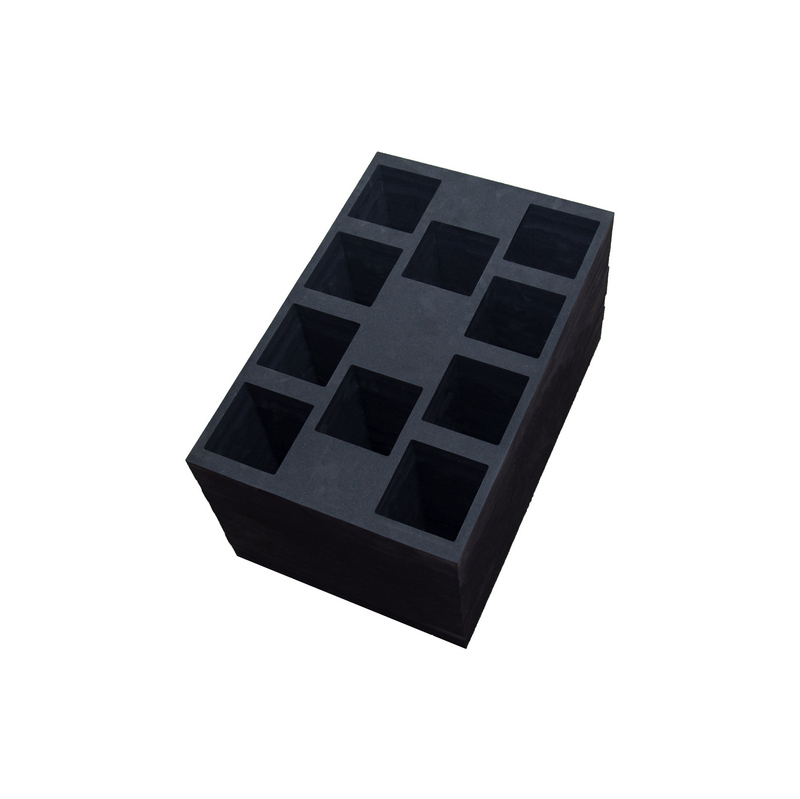

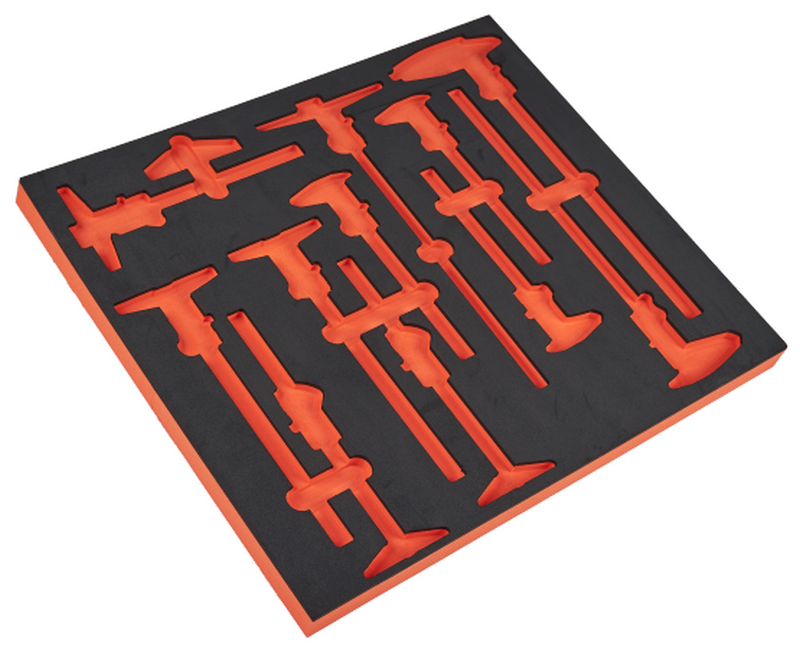

Examples of realizations

Take a look at our selected projects that demonstrate the wide range of applications for our protective foam solutions. Our innovative solutions provide reliable protection and a perfect fit for any project.

Order logistics

Are you interested in our services?

1. Placing an order

Order can be completed by filling out the form or by phone.

2. Measurement

Measurement of tools and objects under which foam inserts will be dedicated.

3. Creation of a 3D model

One of the stages of the order is the creation of a 3D module of the ordered product.

4. Acceptance of the project

In the absence of comments from the ordering party, it is possible to send the project for implementation.

5. Implementation

The ordered item will be made with a precision CNC machine tool according to the approved 3D model.

6. Satisfaction

The customer gets the product according to the order placed.

CNC milling and cutting

We have experience in milling 2D and 3D materials for both unit and mass production.

The precision of the machining method results in an extremely precise product.