Shadow boards for tools

Shadow boards are a visual method of storing tools and other work items. No other method guarantees such a degree of orderliness and safety. Find out how the shadow board will help you keep your tools tidy, and why it should be present in every workshop, manufacturing facility, or other workplace.

Learn more about shadow boards for tools

Shadow boards for tools – what are the benefits for the company?

TShadow boards bring a number of benefits that streamline your workflow with tools, such as sorted by size of keys or screwdrivers. What amenities will appear for employees after introducing shadow boards into the workplace?

- Tool recognition – thanks to the shadow tables, you can easily recognize the tool you need, and after finishing work, you can easily find its storage location on the outline of a characteristic shape. It will definitely make work smoother and prevent the employee from wasting time searching for the item.

- Checking the condition of items – if the tool is not in the intended contour, it may mean that it has been lost or put in the wrong place.

- Better care of your tools – Some items can be damaged easily when improperly stored. The tool shadow board guarantees the safety of items, which is especially important when the cost of purchasing new ones would be high.

- Ergonomics – shadow boards can be designed for the frequency of use of individual tools – the most used ones should be at the operator’s fingertips, while those less used may be a little further away.

The main benefit of using shadow boards will of course be the optimization of time and workflow. All of this will also significantly reduce its costs. Therefore, shadow boards are a very cost effective investment in safety, workflow and resource care.

Shadow boards – what is this method?

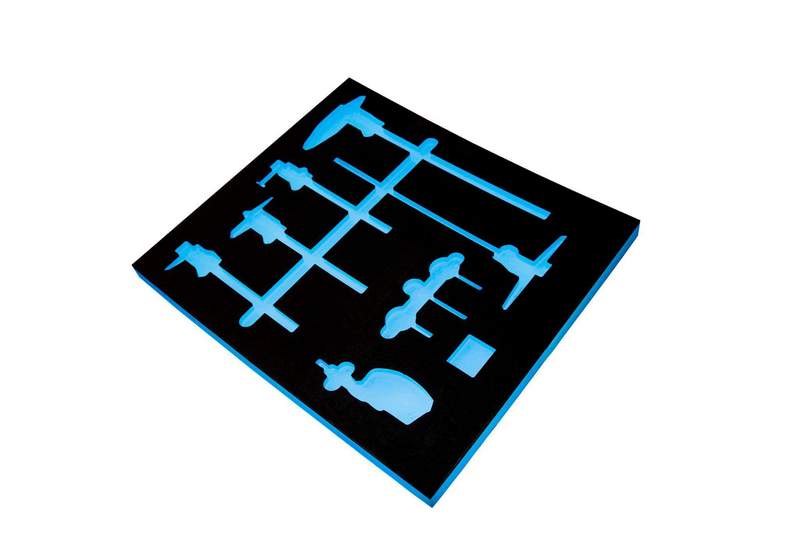

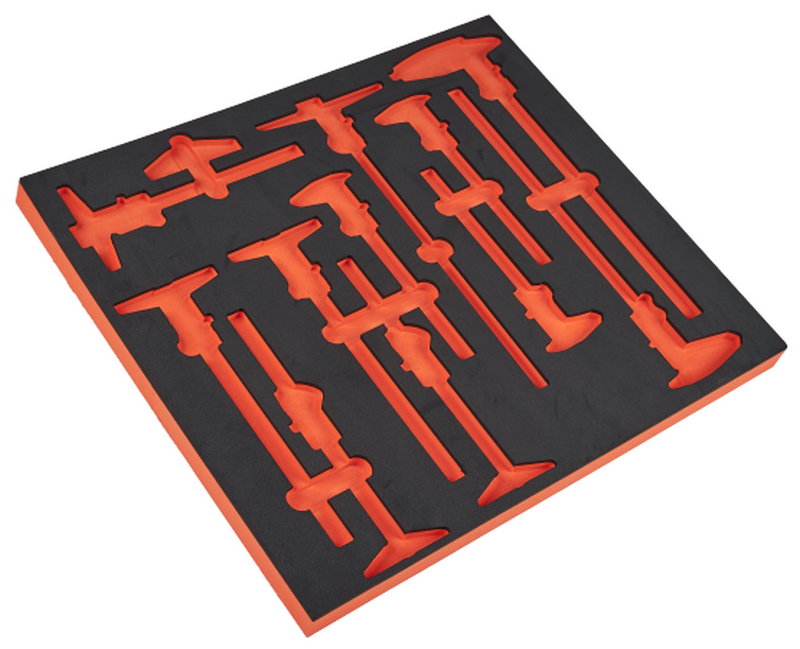

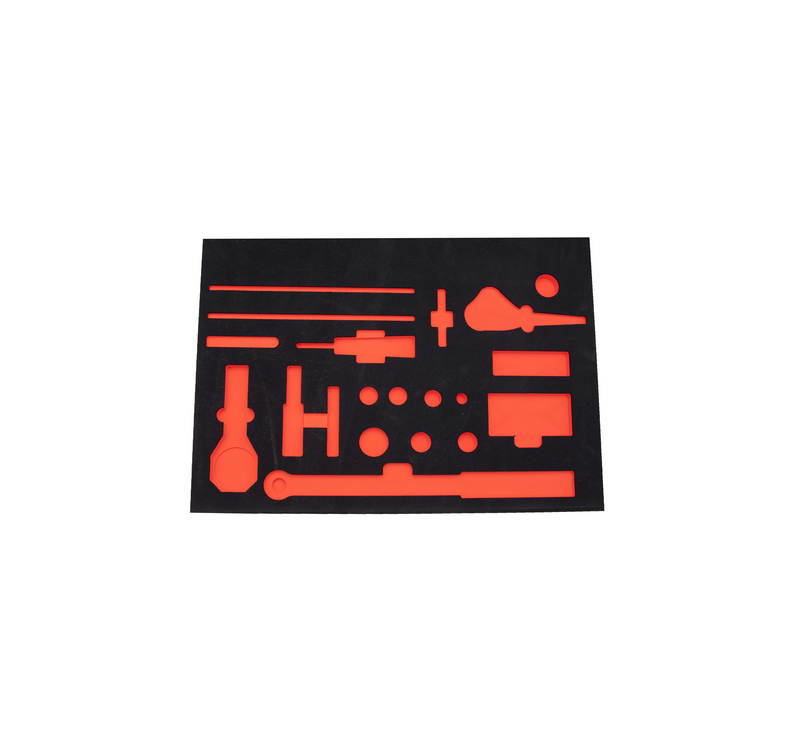

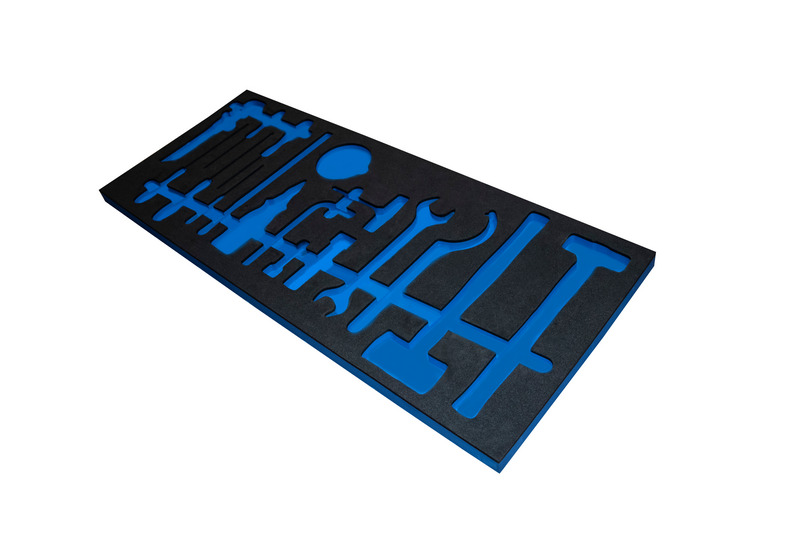

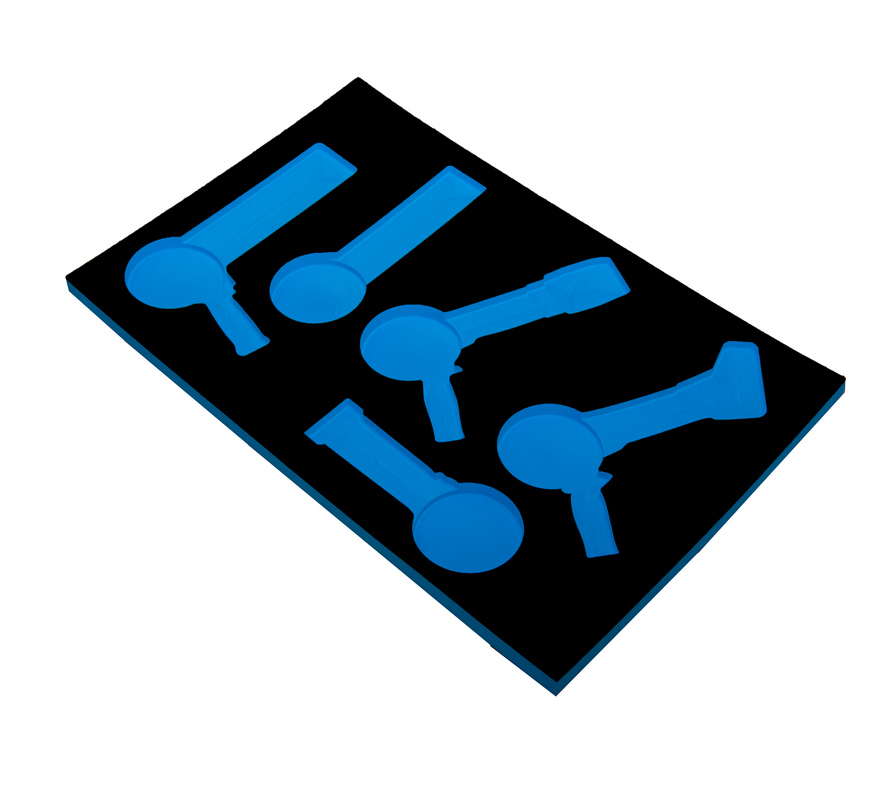

The shadow board for tools consists of contours cut out in the foam, the shape of which corresponds to the shape of individual tools or devices used during work. Thanks to this, each of the tools has its own dedicated place to which it is ideally suited. Lack of a tool in the correct slot means that it is in a place where it may endanger the safety of workers, machines or products.

Shadow board – foam in two colours

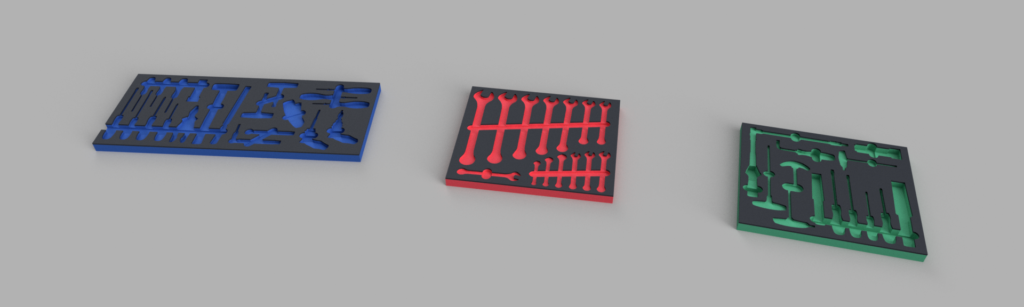

Our method of producing the best shadow boards is to use foams in two colors. Due to the fact that the background under the tool outline is in a bright color, the outline is much more visible, which makes it easier to put the tool back in its place. In addition, the lack of any item will be immediately noticeable, thanks to which employees can start looking for it or notify their supervisor about the lack of a given tool.

What’s more – the colors often serve as a marking of individual zones in the plant. Therefore, in each of the factory departments, there may be shadow boards with foam in different colors, which in turn will correspond to the colors with which the tool is marked. Thanks to this, each tool used for work can be easily put back in place, even if for some unknown reason it will be in a completely different part of the plant.

What form do shadow tablets take?

We produce boards that can be used as drawer inserts or put them directly on the countertop in a designated place at the workplace. If you need to have your tools at hand, we will also make boards for you ready to be mounted on specially prepared frames, thanks to which you can freely design an ergonomic workplace.

Shadow boards and FOD control

Some industries are well aware of the risks posed by tools left in the wrong places for work. A screwdriver left in an engine that is run for inspection can cause enormous damage by damaging the hydraulics, causing a short circuit in the electrical system or causing mechanical damage. This applies to both manufactured components – e.g. aircraft engines – and the maintenance department.

Thanks to the use of shadow boards, it is much easier to perform Foreign Object Damage control, i.e. checking whether there is a risk of damage due to the presence of foreign objects, e.g. left tools. The lack of a tool in its outline on the board should light the employees’ lamp and persuade them to check, for example, the engine.

Shadow boards – necessary in the 5S system

More and more factories are choosing to optimize their workflow by introducing the 5S system, which makes it easier to keep order and cleanliness, and also has a positive effect on efficiency and shortening the working time. The 5S shadow board is part of the workplace infrastructure that is instrumental in successfully operating under the 5S principles.

What is the 5S system?

55S is a set of rules aimed at increasing work efficiency and increasing its safety. The 5S system takes its name from the next five steps aimed at achieving the desired effect. They are:

- sorting – leaving only the necessary items at the workplace,

- set in order – customise the work area to improve efficiency. Keep important materials nearby. Implement visual organisation to streamline workflow and improve efficiency,

- standardization – introducing clear and uniform distribution standards for all employees of this position,

- systematics – that is, a clear marking of the entire assortment used during work,

- self-discipline – developing the habit of keeping an eye on the previous points. Ensure that 5S is a long-term, company-wide goal. Analyse results, hold team meetings and train workers on the importance of 5S.

The ultimate 5S action consists in preparing workstations and common spaces in such a way as to facilitate fast, effective and safe work. This is achieved by designating locations for specific activities related to the job. These can be, for example:

- operator position,

- storage fields for finished products,

- storage of semi-finished products or components,

- waste container,

- tool storage place,

- zones excluded from use / safety zones,

- communication paths.

Colors are most often used to designate individual zones. The adoption of one color to designate a specific zone increases the safety of employees throughout the plant, not only at their position. Shadow boards can be colored according to the marking in a given zone.

Board 5S – how does it help at work?

The 5S board located within the workplace will help to protect each point of the system. Freedom of its design will enable the construction of such a board on which only the necessary tools for work at a given position (sorting) will fit, they will have their own place for storage (set in order), will be visible and available to every person performing the work (standardization), and will also be marked exactly (systematics).

FAQ

Answers to frequently asked questions