Polyethylene – what is it and why is it worth knowing about? Discover the material that has revolutionized everyday life

There are few materials that have revolutionized the world in such a quiet way. You won’t find it on the front pages of newspapers or in TV commercials, and yet it accompanies you almost every day – in your shopping bag, charger cable, food packaging, and even in the pipes hidden in the walls. Polyethylene, that’s what it’s called, is an unassuming but absolutely key element of modern industry and everyday life. What exactly is it? Where did its popularity come from? And why is it increasingly being chosen as a protective material in the form of foams or protective inserts? Take a look behind the scenes of the material without which neither the world of logistics nor modern construction would work.

Polyethylene – what is this material and why would modern industry (or your daily life) not work without it

If you’re wondering what polyethylene is, the answer isn’t as obvious as it might seem. On the one hand, it’s just plastic. On the other hand, it is one of the most important industrial materials of the last decades, without which many industries simply could not function. You can find it in shopping bags, food wrap, sewer pipes, and even in car parts. Yes, it is polyethylene, which, despite its “invisibility” in everyday life, has a huge impact on how the modern world functions.

It’s no coincidence that it’s called the material of all time. It’s light, flexible, durable, and cheap to produce – four characteristics that together create a recipe for global success. Polyethylene is a polymer with an exceptionally simple chemical structure, but this simplicity is its greatest strength. Thanks to it, it’s possible to adjust the material’s properties to specific needs – from ultra-thin foil to thick-walled chemical tanks. What’s more, this material is still evolving. Bio-based varieties are emerging that fit into the sustainable production trend. And that’s just the beginning.

How is polyethylene made? Take a look behind the scenes of one of the most processed materials in the world

Although the finished product – a garbage bag, a protective film, or a pressure pipe – looks quite unassuming, the path that polyethylene takes from raw material to application is much more complex. The production process begins with the polymerization of ethylene, which is the process of combining simple molecules into a long chemical chain. But that’s where the magic begins – because the way this reaction proceeds directly affects the type of polyethylene that will be produced and what it can be used for.

High-pressure production (LDPE), conducted at truly extreme parameters – reaching 3,000 atmospheres – allows for obtaining a flexible, soft material with a very loose structure. On the other hand, the low-pressure method (HDPE, LLDPE) results in a much stiffer and more resistant material, which works well in construction installations, for example. Importantly, both technologies are equally important today – there is no better or worse version. It all depends on the intended use and the desired properties of the final product.

This can be seen in the example of specialized polyethylene foams, which are created using carefully selected physical and chemical processes. XPE foam (cross-linked polyethylene foam) is a cross-linked foam characterized by exceptional durability, flexibility, and closed-cell structure, making it suitable for thermal and acoustic insulation, among other uses. EPE (expanded polyethylene foam) is a type of foamed polyethylene that provides excellent shock absorption, which is why it is used in protective packaging. However, ESD foams have antistatic properties, which makes them an ideal choice for protecting electronic components sensitive to electrostatic discharges. All these varieties have one thing in common – the possibility of precise fitting to the application due to the unique properties of the basic raw material, i.e. polyethylene.

What makes polyethylene so versatile? Learn about its properties and discover where its strength lies

Are you wondering why polyethylene is so popular and versatile? The answer lies in its unique physicochemical properties, which are hard to find in a single material. First of all, its incredible chemical resistance. This material is practically non-reactive with most substances – acids, bases, solvents, and moisture are no match for it. It is perfect for contact with food, chemicals or water.

Second, it is lightweight but very durable. Polyethylene can be easily molded, stretched, and cut, yet it maintains its durability for many years. It can withstand temperature changes and is not easily damaged by impact. Third, its electrical insulation. This makes it an ideal material for the electrical installation industry. And of course, its low production costs and ease of recycling only strengthen its position as a material “for now and for the future.” So it’s not just that it’s cheap. It’s that the set of features it offers makes it indispensable in many applications.

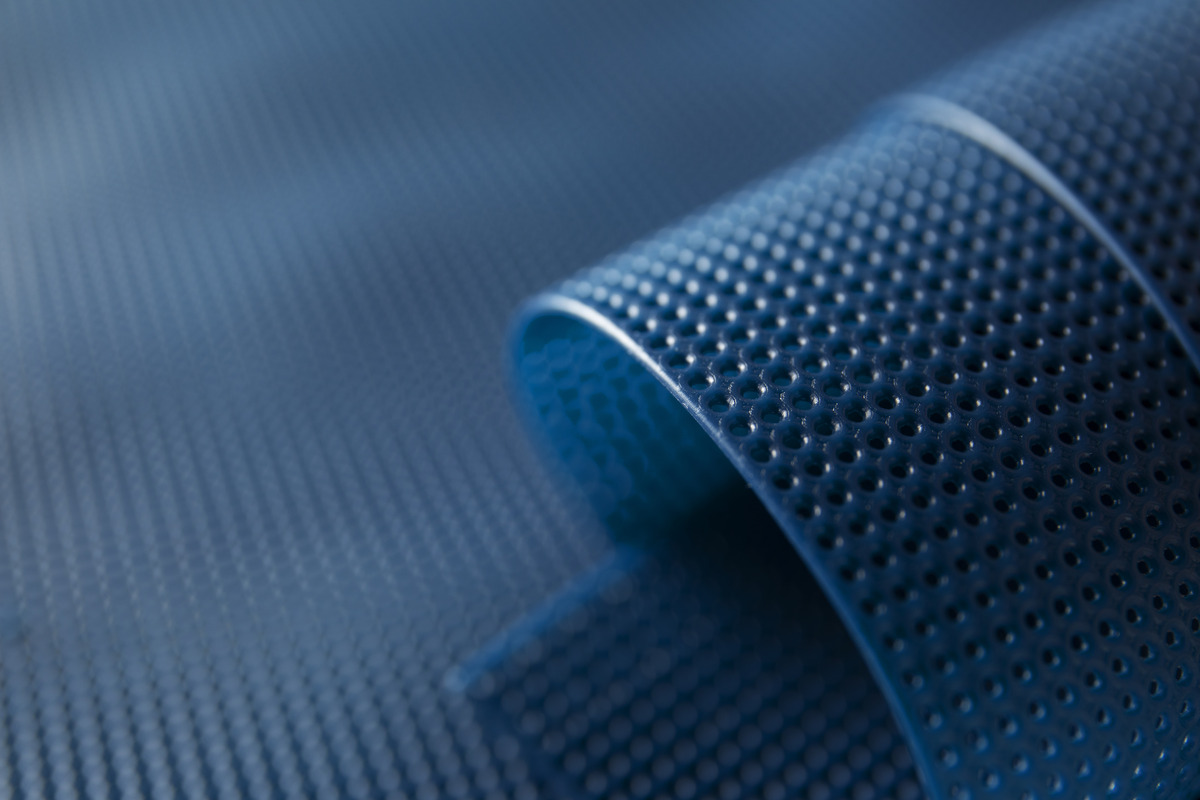

Choose closed-cell foam – resistant to moisture, shock, and abrasion!

Where do you encounter polyethylene on a daily basis? From lunch wrap to industrial pipes – see how much you need it

You don’t have to work in industry to be exposed to polyethylene every day – even if you don’t realize it. Food wrap, bags, disposable packaging, and even bottles and beverage closures – all of these are probably made from this material. His invisible presence is a hallmark of modern technology that is supposed to be convenient, lightweight, and functional at the same time. And although you often don’t pay attention to them, many things would just not work without them.

But it’s not just the consumer world. In construction, polyethylene is used to make sewer pipes, moisture-resistant insulation, and roofing membranes. In the chemical industry, it is used to create tanks and pipelines resistant to aggressive media. In the automotive industry? You’ll find it in interior elements, glove compartments, and trunks. In electronics? As insulation for wires and cables, thanks to its dielectric properties. It’s hard to imagine an industry where polyethylene wouldn’t be used – and that’s what makes it such an important material in today’s world.

Why is polyethylene so great for foams and protective packaging? See how technology serves product safety

The use of polyethylene in the form of foam (PE foam) is one of the best examples of how technology can respond to real needs. Fillings and protective packaging, edge protection or insulation of sensitive components – all of these are based on the properties that this material offers in its foam version. It is lightweight, water-resistant, flexible, and yet durable enough to protect delicate components from damage.

PE foam is used in the transportation, storage, and display of goods, among other things. It provides excellent shock absorption, does not absorb water, does not permanently deform under pressure, and is easy to shape into a specific form. This makes creating protective inserts for suitcases, chests or shadow boards fast and cost-effective. It is also significant that this foam is chemically neutral and does not react with other materials, which is why it is also successfully used in medicine and the electronics industry. If you need safe transportation or professional product presentation, this is the solution you should consider.

We share our expertise in the design and production of shadow boards, protective packaging, and inserts made from PE foam. For years, we’ve been supporting the aerospace, medical, and automotive industries by delivering solutions tailored to individual needs. We combine the precision of CNC machining with an eco-conscious approach and technical consulting. Our creations focus on quality, ergonomics, and reliability.