Securing items during transport – take advantage of the excellent properties of polyethylene foam

Damage to goods during transport is a more common problem than you might think, which is why it is very important to secure your cargo properly during transport. Find out how you can use polyethylene foam for this purpose and what excellent results you can achieve by choosing foam fillers and packaging. At Protective Foam Solutions, we will prepare customised inserts for you to ensure maximum protection for your transported items.

Securing goods during transport – why is it so important?

Proper securing of cargo during transport helps to avoid significant financial losses. Items are exposed to damage during transport regardless of the means of transport. Strong shocks occur, which can cause deformation and abrasion. This is particularly noticeable with various types of items made of delicate materials. No one wants to arrive at the delivery location and find that some of the goods are damaged and unusable. Every business owner knows that such losses are unacceptable.

Therefore, we must ensure that the cargo is secured both during transport within the plant and during road transport. For this purpose, it is best to use foam fillers and protective foam packaging – this will guarantee excellent protection for the transported items.

Foam fillers and protective foam packaging – the perfect way to secure loads

There are various ways to secure cargo during transport, but today we will present the most effective and outstanding solution. We are talking about foam fillings, which enable safe internal or external transport of all sensitive products – regardless of their type, size or material. This is an extremely versatile solution that is an excellent alternative to the commonly used polystyrene.

Foam fillers for packaging are used to perfectly fill the space between the walls of the packaging and the transported product. Eliminating any possibility of movement of goods inside prevents dents and abrasions, completely eliminates shocks and ensures resistance to damage caused by stress.

Polyethylene foam is also ideal for transporting various types of equipment, which is why it is useful for many companies offering services to customers. Machines needed for business operations will last longer and retain their properties when properly protected. Throwing them carelessly into the back of your van is asking for trouble – valuable equipment can be damaged, which will result in high costs. It is therefore worth ensuring that you have the right foam packaging, which is excellent at preventing damage to tools or electrical equipment.

Load securing – why choose PE foam?

The excellent properties of PE foam allow for excellent protection of cargo during transport. What makes it provide such excellent protection?

PE polyethylene foam is distinguished primarily by its very high level of shock absorption, which makes it ideal for transporting sensitive goods. It provides excellent protection even during heavy shocks and vibrations. There will also be no problem with the sterile conditions that some items may require – PE foam does not allow air to pass through, and therefore does not allow dust to enter. It also does not react chemically with other materials, so it will not affect the goods in any way. This makes it ideal for use as packaging for food products.

Order customised PE or XPE foam fillings and packaging – protection you can trust!

By using this material, we also ensure safety, as it is non-flammable. It is also antistatic, which makes it suitable for transporting electronic equipment. We protect modern equipment susceptible to electrostatic discharge, safeguarding its components from damage.

All of the above features mean that foam packaging and fillers provide much better results than other methods of securing loads. They are increasingly replacing polystyrene, significantly surpassing it in terms of mechanical and physicochemical properties.

Secure your goods with XPE foam – take advantage of Protective Foam Solutions’ offers

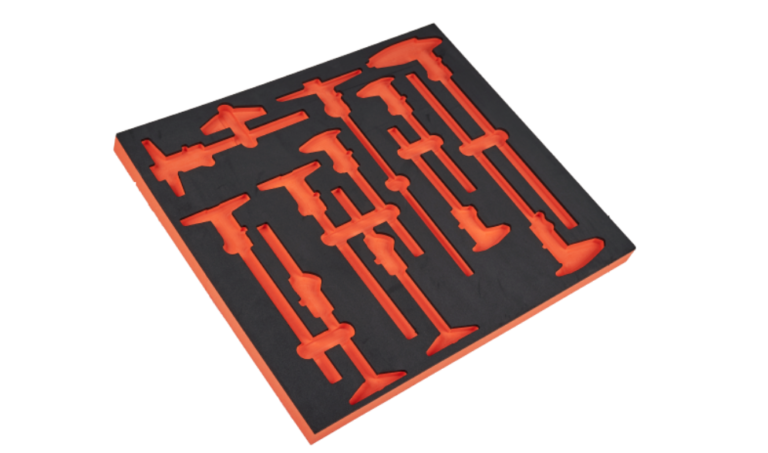

If you are looking for a top-quality product, we have exactly what you need. Our offer includes cross-linked XPE polyethylene foams in various thicknesses, which you can adapt to your requirements and the specifications of the equipment or goods being transported. Black foam can be ordered in thicknesses from 10 mm with no height restrictions, while two-colour material is available in standard thicknesses of 30 mm, 35 mm, 40 mm and 50 mm.

The available colour options are:

- black and blue,

- black and red,

- black and orange,

- black and yellow,

- black and green.

We are able to create a precise 3D model using CAD programming, accurately determining all the dimensions of the item we intend to put in the packaging or transport in a case. This allows us to create a outline that matches the dimensions and shapes of your goods. A perfectly tailored filling guarantees the highest level of protection.

Contact us today and we will design modern foam fillings especially for you, ensuring excellent protection during transport and storage of various types of products and tools. We invite you to take advantage of our services – Protective Foam Solutions.

We share our expertise in the design and production of shadow boards, protective packaging, and inserts made from PE foam. For years, we’ve been supporting the aerospace, medical, and automotive industries by delivering solutions tailored to individual needs. We combine the precision of CNC machining with an eco-conscious approach and technical consulting. Our creations focus on quality, ergonomics, and reliability.