Polyethylene foam – XPE foam

XPE polyethylene foams are widely used in the automotive industry, where they serve as insulation and noise and vibration dampening material in vehicles. In the packaging industry, XPE foam is used to protect fragile products during transportation, protecting them from mechanical damage. In the construction industry, it is used as thermal and acoustic insulation, thanks to its excellent insulating properties. XPE is also used in the production of sports and protective mats, where its flexibility and strength provide comfort and safety for users. In addition, in the electronics industry, the foam is used to protect sensitive components from shock and static electricity buildup.

Learn more about XPE foam

Polyethylene foam – application

XPE foam, thanks to its properties, is really widely used in many industries.

In industry, XPE foam is used as an insulating and protective material, providing shock resistance and excellent thermal and acoustic insulation.

In e-commerce, the foam is used to protect products during shipping, protecting them from mechanical damage, and also gives products uniqueness due to its smooth texture.

In transportation, XPE foam is used to protect fragile cargo, minimizing the risk of damage during transit.

Polyethylene foam in packaging production

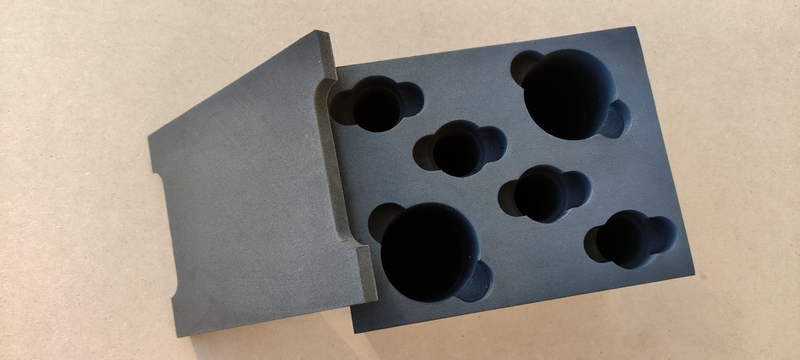

We, of course, are most interested in the use of XPE foam in the production of packaging and suitcase inserts. Its previously mentioned properties make it the most common use of polyethylene in the transportation industry.

This is because polyethylene foam protects goods from:

- damage caused by shock or vibration,

- electrostatic discharges,

- scratches and bruises,

- moisture,

- contaminants in the air.

Polyethylene foam for packaging – properties

XPE foam has found its use in the packaging industry due to a number of properties that make inserts made of this material effectively protect the transported goods from mechanical damage and many external factors. Find out what properties of polyethylene foam will effectively protect transported items from damage.

Advantages of XPE foam

Total abrasion resistance

This is one of the most important features, thanks to which polyethylene foam retains its durability. This definitely distinguishes it from the commonly used polystyrene foam, which very often breaks, crumbles or cracks during transport, thus reducing the safety of the goods. Thanks to its resistance to abrasion and tearing, XPE foam can be used to transport items with both smooth and sharp surfaces and ends.

Resistance to moisture

Polyethylene foams do not absorb moisture. As a result, items transported in protective packaging with a polyethylene insert are not exposed to the harmful effects of water. The moisture resistance of polyethylene foam also prevents the formation of mold or mildew. XPE foam is resistant not only to water, but also to chemical solvents. This is of great importance in virtually any case – from electronic equipment to valuable items such as specimens or art collections.

Shock absorption

XPE polyethylene foam is characterized by a high level of shock absorption, making it ideal for transport, when goods are heavily exposed to shocks and vibrations. Effective cushioning makes foam inserts for packages or suitcases, making it possible to safely transport highly sensitive measuring or calibration instruments, for example.

Impermeability

Polyethylene foam is impermeable to air and, consequently, to the dust inside it. As a result, PE packaging inserts make it possible to transport goods that require sterile conditions, such as medical or laboratory equipment.

Chemical neutrality

Polyethylene foam does not have any chemical reactions with the goods packed in it. This makes it possible to use XPE also when transporting food products. Polyethylene foam is also characterized by its non-flammability, which further enhances the safety of delivery, while its resistance to Skydroll guarantees safety during air transportation.

Antistaticity

The anti-staticity of polyethylene foam is a feature that gives it another application, namely the ability to transport electronic equipment. Modern equipment, in which components have undergone a process of miniaturization, is particularly prone to malfunction or failure as a result of electrostatic discharge (often not sensed by humans at all). Polyethylene foams dissipate the electrostatic charge so that goods are not exposed to damage.

Varying densities

Polyethylene foam can come in different values of density expressed in the unit kg/m3. Depending on this parameter, the foam will effectively protect items of greater or lesser weight.

XPE foam – an alternative to polystyrene foam

In the packaging industry, polyethylene foams are increasingly replacing polystyrene, which does not have such good mechanical and physicochemical properties as polyethylene. First of all, it is flammable, definitely more brittle, less flexible, and more difficult to form into the desired shape. It also does not guarantee such good shock and vibration absorbing properties. Unlike Styrofoam, polyethylene foam is a material that can be recycled for reuse. Therefore, it is a much more environmentally friendly choice.

How is polyethylene foam made? Cross-linked and non-cross-linked foam

Chemically crosslinked polyethylene foam is produced by adding a crosslinking agent to polyethylene, which forms bonds between the polymer chains during the foaming process. Once the polyethylene is mixed with the chemical, the material is heated, which activates the crosslinking agent and causes foaming and simultaneous crosslinking of the structure. This process results in a closed-cell foam with greater strength and flexibility compared to uncrosslinked polyethylene.

How do we use XPE foams in packaging production?

Our offer includes making customized shadow boards, and inserts for suitcases and packages. We will prepare for you polyethylene inserts for boxes or suitcases, which will perfectly fill the entire space between the transported item and the walls of the packaging, eliminating the possibility of any movement of goods inside.

What foams do we offer at PFS?

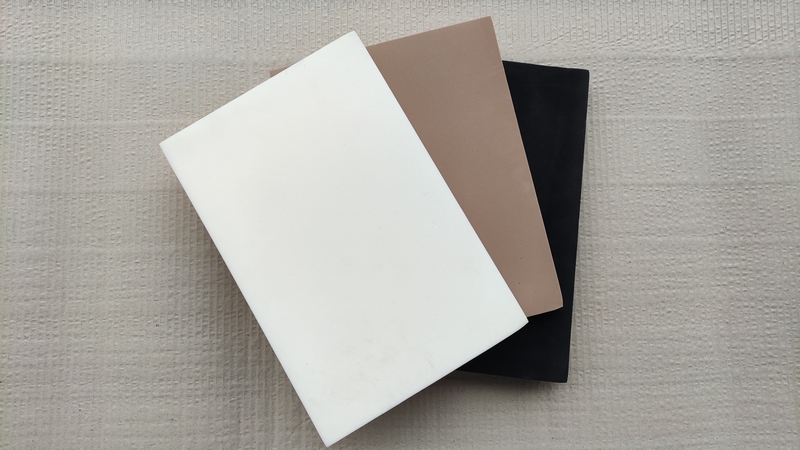

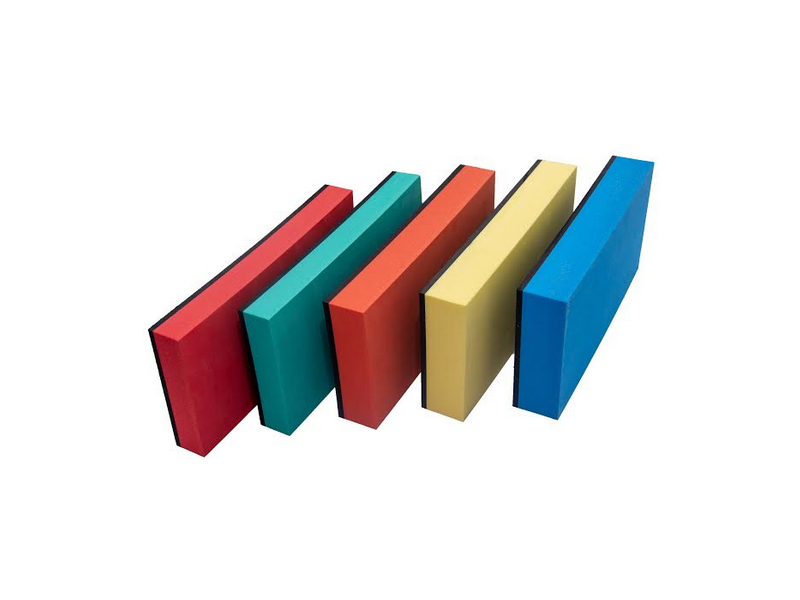

XPE polyethylene foams come in many colors such as:

- black,

- white,

- blue, green, yellow, red and gray,

- two-color with a 5 mm thick black layer and a layer in the color of your choice.

The foams are available in 2000×1000 mm , 1200×2100 mm and 1200×2000 mm sheets in thicknesses ranging from a few millimeters to 100 mm.

The foams also come in different densities.

Cross-linked polyethylene foam – Plastazote

Compared to other XPE foams, Plastazote® exhibits significantly better performance during hot molding. Plastazote® products are designed to achieve optimum performance with minimal weight. With no chemical additives and a uniform density and cell structure, Plastazote® is the lightest cross-linked foam available on the market.

The material comes in a variety of densities as low as 15kg/m3 and various color versions, and is non-toxic.

Plastazote polyethylene foam is widely used in a variety of industries due to its properties such as lightweight, chemical resistance and excellent cushioning. Here are some key industries where it is used.

Automotive: Plastazote is used for protective inserts in safety systems,

Aerospace: In this sector, the foam is used to protect sensitive components such as electronics and structural components, providing insulation and cushioning during transport and operation.

Packaging and transportation: Foam is used for inserts and protection in packaging, which protects fragile items during transportation, minimizing the risk of damage.

Construction: In this industry, foam is used as an insulating material that offers excellent thermal and acoustic insulation, and as components in sealing systems.

But also in many others such as the medical, railroad and marine industries.

FAQ

Answers to frequently asked questions